Workplace Safety Essentials: Key Components of a Safe Working Environment

Essential components of a safe work environment

A safe work environment forms the foundation of any successful business operation. Beyond legal compliance, workplace safety straightaway impact productivity, employee morale, and organizational reputation. Understand what constitute a comprehensive safety framework help businesses protect their well-nigh valuable asset — their people.

Physical safety measures

The virtually visible aspects of workplace safety involve physical protections design to prevent accidents and injuries.

Proper facility design and maintenance

Safe workplaces start with thoughtful design. Workspaces should feature:

- Adequate lighting in all areas

- Non-slip flooring, peculiarly in high traffic or potentially wet areas

- Clear pathways free from obstacles or trip hazards

- Proper ventilation systems to maintain air quality

- Regular maintenance schedules for all equipment and facilities

- Accessible emergency exits that remain unblocked

Proactive maintenance prevent many workplace accidents. Organizations should implement schedule inspections to identify and address potential hazards before they cause harm.

Personal protective equipment (pPPE)

When hazards can not be wholly eliminate, proper PPE serve as a critical defense. A comprehensive PPE program include:

- Task appropriate protection (gloves, goggles, helmets, respirators, etc. )

- Proper sizing and fit for all employees

- Regular inspection and replacement of damage equipment

- Train on correct usage and maintenance

- Clear policies regard when and where PPE must be wear

Employers must not exclusively provide appropriate PPE but besides ensure employees understand its importance and proper use.

Emergency preparedness

Eventide with prevention measures, emergencies can occur. Safe workplaces maintain:

- Clear mark emergency exits

- Functional fire suppression systems (sprinklers, extinguishers )

- First aid supplies promptly accessible throughout the facility

- AED (automated external defibrillator )devices in appropriate locations

- Emergency action plans for various scenarios (fire, medical emergency, natural disaster )

- Regular drills to practice emergency procedures

Preparedness extend beyond equipment to include train response teams and establish communication protocols during emergencies.

Source: iasexam.com

Hazard controls and prevention

Effective safety programs identify and mitigate workplace hazards use a systematic approach.

Hazard identification and risk assessment

Organizations should conduct regular evaluations to:

- Identify potential physical, chemical, biological, and ergonomic hazards

- Assess the likelihood and potential severity of each hazard

- Document findings in accessible risk registers

- Prioritize hazards base on risk level

- Develop specific mitigation strategies for identify risks

These assessments should occur both routinely and whenever processes or equipment change.

Control hierarchy implementation

When address identify hazards, organizations should follow the control hierarchy:

-

Elimination

entirely remove the hazard -

Substitution

replace the hazard with something less dangerous -

Engineering control

isolate people from the hazard -

Administrative controls

change how people work -

Personal protective equipment

protect the worker with pPPE

This approach ensure that the virtually effective controls receive priority consideration.

Machine and equipment safeguards

Machinery present significant workplace hazards. Safe environments include:

- Physical guards on move parts and pinch points

- Emergency stop mechanisms within easy reach

- Lockout / ragout procedures for maintenance operations

- Regular equipment inspections and preventive maintenance

- Clear operational procedures post near equipment

These safeguards prevent many of the well-nigh serious workplace injuries.

Health and wellness considerations

Safety extend beyond accident prevention to include overall employee health protection.

Ergonomic design

Proper ergonomics prevent repetitive strain injuries and improve productivity. Workstations should feature:

- Adjustable seating with proper lumbar support

- Computer monitors position at eye level

- Keyboards and input devices that minimize strain

- Adequate desk space and organization

- Anti fatigue mats for standing workstations

- Tools design to reduce physical stress

Regular ergonomic assessments help identify improvements and address individual needs.

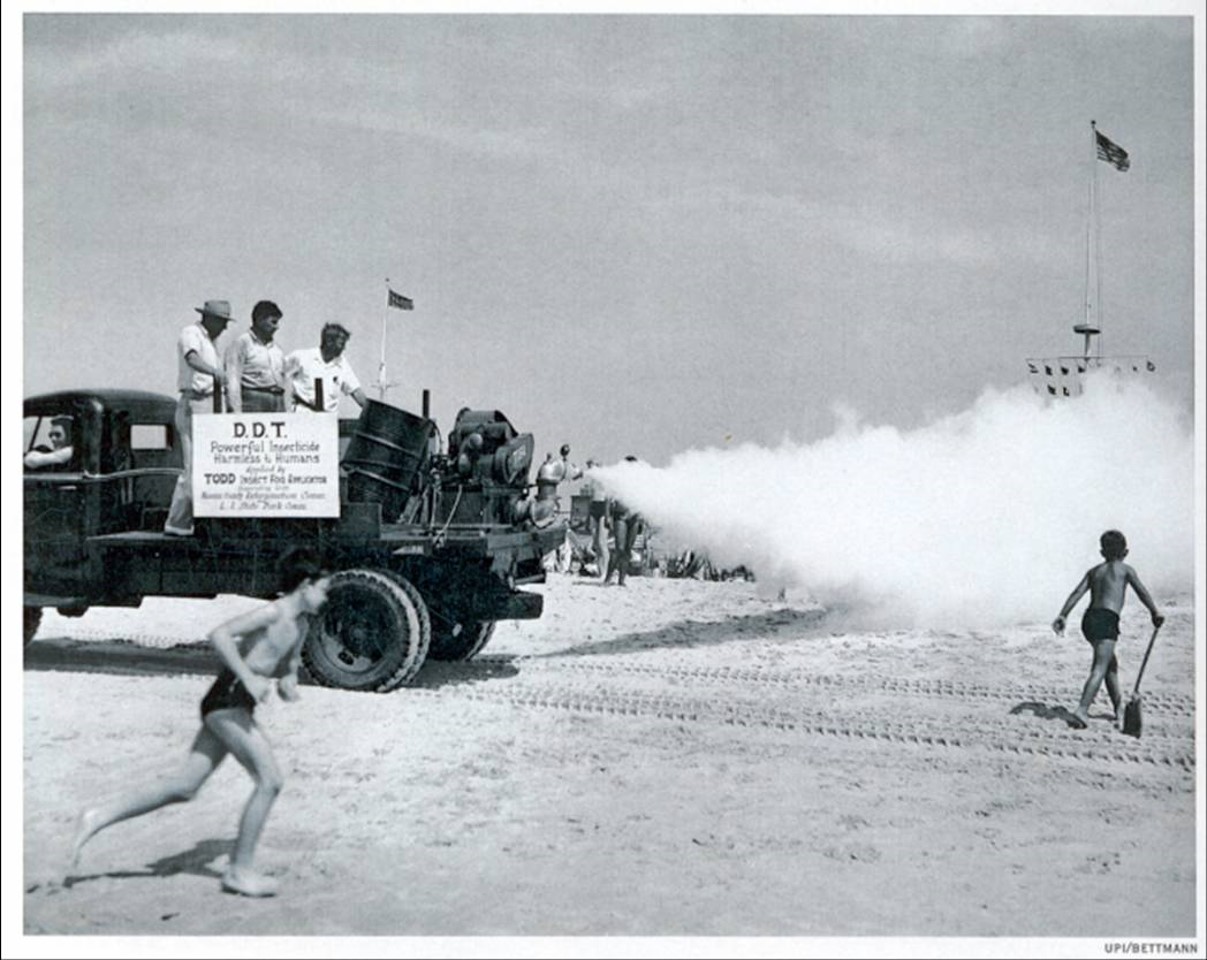

Indoor air quality management

Clean air importantly impact employee health. Effective air quality management include:

- Proper ventilation systems with regular maintenance

- Monitoring and control of airborne contaminants

- Humidity control to prevent mold growth

- Policies regard chemical use and storage

- Smoke-free workplace policies

- Regular testing of air quality parameters

Poor air quality contribute to respiratory issues, headaches, and decrease productivity.

Noise control

Excessive noise damages hearing and increase stress. Noise management should include:

- Engineering control to reduce equipment noise

- Sound barriers between noisy operations and other work areas

- Hear protection when noise levels exceed safe limits

- Regular noise level monitoring

- Audiometric testing for employees in high noise environments

Level moderate noise levels can impact concentration and communication quality.

Safety culture and training

Physical safeguards solely can not ensure workplace safety without a support culture.

Source: icrjobs.com

Comprehensive safety training

Effective training programs include:

- Initial safety orientation for all new employees

- Job specific safety training for particular roles

- Regular refresher courses on safety procedures

- Specialized training for high risk tasks

- Documentation of all complete training

- Verification of understanding through testing or demonstration

Training should use various methods (hands on, visual, write )to accommodate different learning styles.

Clear communication systems

Safety information must flow freely throughout the organization:

- Visible safety signage use standardized symbols

- Regular safety meetings and briefings

- Accessible safety data sheets for all hazardous materials

- Multiple channels for report safety concerns

- Feedback mechanisms for safety suggestions

- Transparent sharing of incident data and prevention measures

Effective communication ensure everyone understand their safety responsibilities.

Leadership commitment

Management play a crucial role in workplace safety through:

- Visible participation in safety initiatives

- Allocation of adequate resources for safety programs

- Recognition of safe behaviors and practices

- Lead by example in follow safety protocols

- Hold all levels accountable for safety performance

- Integrate safety into business decisions

When leadership prioritize safety, employees follow suit.

Psychological safety

A sincerely safe workplace addresses psychological advantageously being alongside physical safety.

Harassment and violence prevention

Workplaces must protect employees from harmful behaviors through:

- Clear anti harassment and anti violence policies

- Confidential reporting mechanisms for incidents

- Fair investigation procedures

- Train on respectful workplace conduct

- Security measures to prevent unauthorized access

- Support resources for affected employees

These measures create an environment where all employees feel secure.

Stress management resources

Workplace stress impact both safety and productivity. Support systems should include:

- Reasonable workloads and deadlines

- Clear job expectations and feedback

- Employee assistance programs (emaps)

- Stress management training

- Flexible work arrangements when possible

- Regular breaks and adequate time away

Manage stress reduce accident risk and improve decision-making.

Inclusion and respect

Psychologically safe environments foster:

- Equal treatment irrespective of background or characteristics

- Opportunities for all employees to contribute ideas

- Recognition of diverse perspectives

- Zero tolerance for discriminatory behavior

- Accessible accommodations for disabilities

- Culture where mistakes can be acknowledged without fear

When employees feel value and respect, they engage more amply with safety programs.

Compliance and continuous improvement

Safe workplaces maintain legal compliance while invariably seek improvement.

Regulatory compliance

Organizations must meet legal safety requirements through:

- Knowledge of applicable regulations (oOSHA state requirements )

- Regular compliance audits and inspections

- Proper record keeping of incidents and training

- Well-timed report to regulatory agencies when require

- Address citations or violations quickly

- Stay inform about regulatory changes

Compliance provide the minimum foundation for workplace safety.

Incident reporting and investigation

Learn from incidents require:

- User-friendly systems for report incidents and near misses

- Non-punitive approach to encourage report

- Thorough investigation procedures

- Root cause analysis beyond immediate factors

- Development and implementation of corrective actions

- Follow up to verify effectiveness of solutions

Each incident provide valuable information for prevent future occurrences.

Performance metrics and benchmarking

Measure safety performance guide improvement through:

- Lead indicators that predict potential issues

- Lag indicators that track outcomes

- Regular review of safety statistics

- Comparison against industry benchmarks

- Set meaningful improvement goals

- Celebrate safety milestones and achievements

What gets measure gets manage — tracking metrics focus attention on safety priorities.

Remote and mobile work considerations

Modern work arrangements require expand safety approaches.

Home office safety

Remote workers benefit from:

- Ergonomic guidance for home workstations

- Equipment stipends for proper setup

- Virtual ergonomic assessments

- Clear work hour boundaries to prevent burnout

- Regular check ins on intimately being

- Resources for address home safety issues

Organizations maintain responsibility for employee safety disregardless of location.

Field worker protection

Mobile employees need specialized safeguards:

- Vehicle safety programs and driver training

- Communication devices and emergency protocols

- Location track for emergency response

- Weather monitoring systems

- Portable safety equipment

- Risk assessment for vary work environments

Mobile workers face unique challenges require tailor safety approaches.

Conclusion

A genuinely safe work environment incorporate multiple layers of protection address both physical and psychological aspects of safety. Organizations that invest in comprehensive safety programs not exclusively comply with regulations but besides benefit from increase productivity, improved morale, reduced costs, and enhance reputation.

Safety is ne’er” completed”—it rrequiresongoing commitment, regular assessment, and continuous improvement. By incorporate all essential components discuss supra, organizations create environments where employees can perform their best work without compromise their well-being.

The well-nigh effective safety programs recognize that protect employees isn’t exactly a legal obligation — it’s a core business value that affect every aspect of organizational success.